Pvb Laminated Glass

One of the main advantages of PVB Laminated Glass is its ability to hold together even when shattered. In the event of breakage, the glass fragments adhere to the PVB layer, preventing them from scattering and causing injury. This feature makes it an ideal choice for applications where safety is a top priority, such as in automotive windshields and building windows.

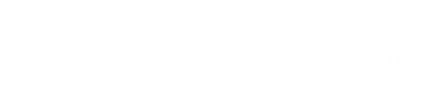

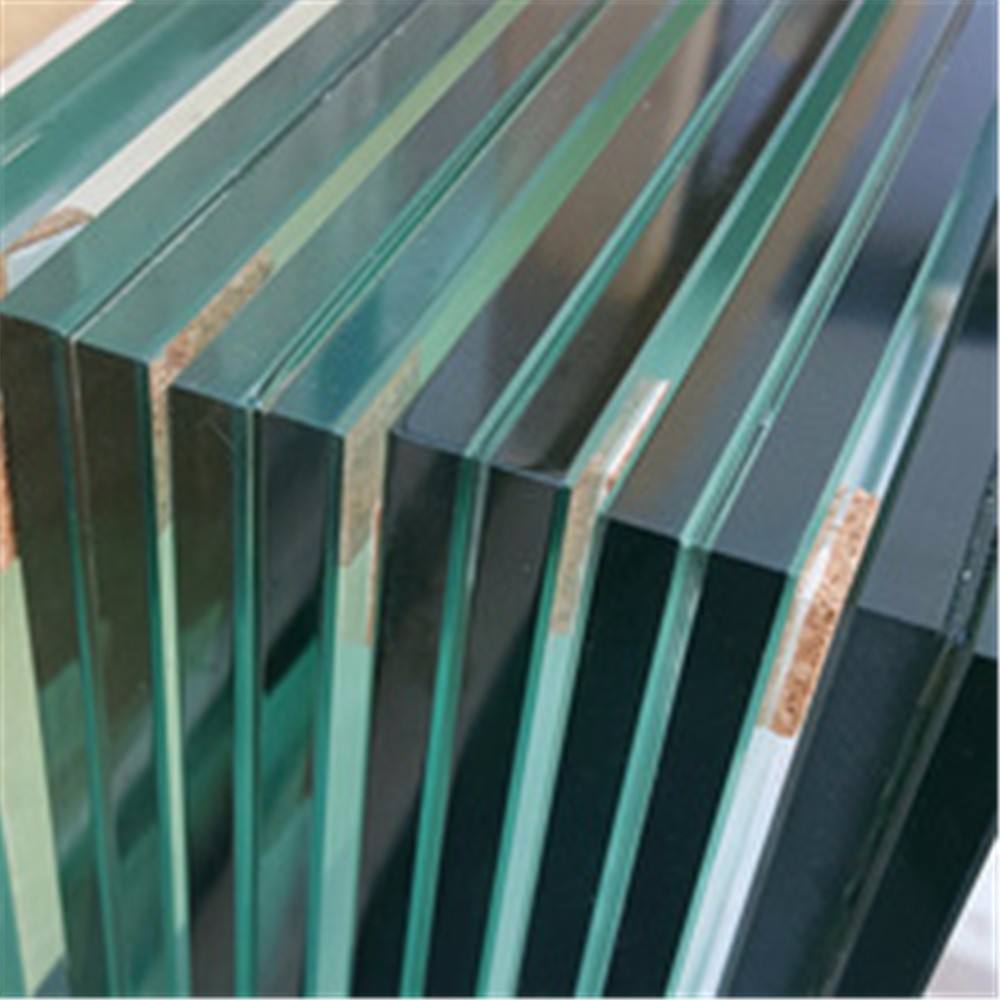

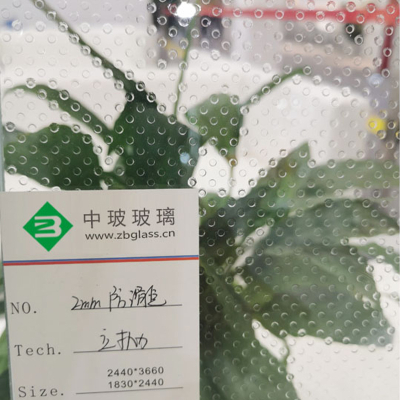

PVB Laminated Glass is a type of safety glass that is made by sandwiching a layer of polyvinyl butyral (PVB) between two pieces of glass. This unique construction provides enhanced impact resistance and safety features.

One of the main advantages of PVB Laminated Glass is its ability to hold together even when shattered. In the event of breakage, the glass fragments adhere to the PVB layer, preventing them from scattering and causing injury. This feature makes it an ideal choice for applications where safety is a top priority, such as in automotive windshields and building windows.

In addition to its safety benefits, PVB Laminated Glass also offers other advantages. It provides excellent sound insulation, reducing noise transmission and creating a more peaceful environment. The PVB layer also acts as a UV filter, blocking harmful ultraviolet rays that can fade and damage furniture, artwork, and other interior finishes.

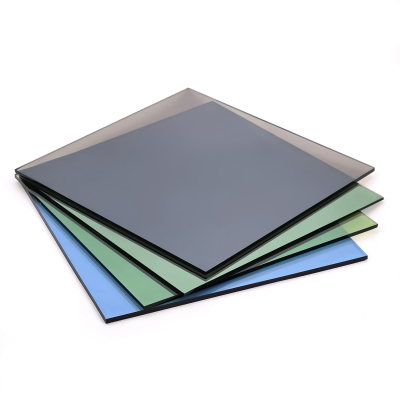

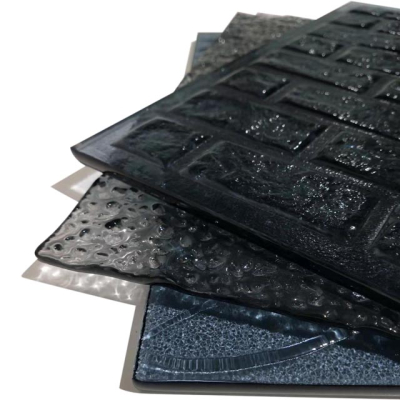

PVB Laminated Glass is highly versatile and can be customized to meet specific requirements. It is available in various thicknesses, tints, and sizes, allowing it to be used in a wide range of applications. Whether it's for commercial, residential, or industrial purposes, PVB Laminated Glass offers a durable and reliable solution.

In conclusion, PVB Laminated Glass is a high-performance safety glass that provides enhanced impact resistance, safety features, sound insulation, and UV protection. It is a versatile and customizable option for various applications, making it an excellent choice for anyone prioritizing safety and durability.